Your Expert Water Chiller Manufacturer

Main Products

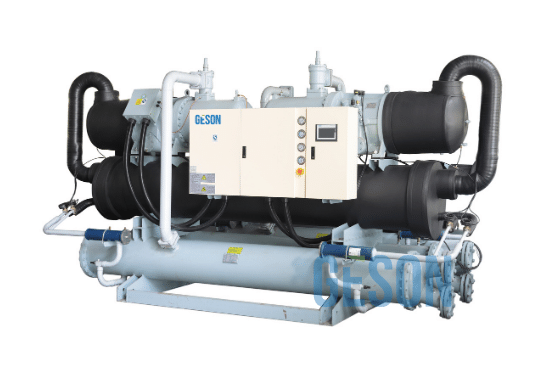

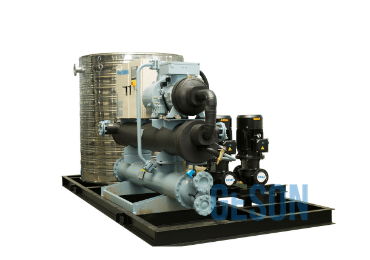

Water Cooled Screw Chiller 12/7℃

- Cooling capacity ranges: 30~4500RT.

- Loading adjusted 100%, 75%, 50%, 25%,0.

- Available with R22/R134A/R407C/R410A and etc.

- Failure-free operation >=40000hours.

- Compact in structure, cover small area, save machine room space.

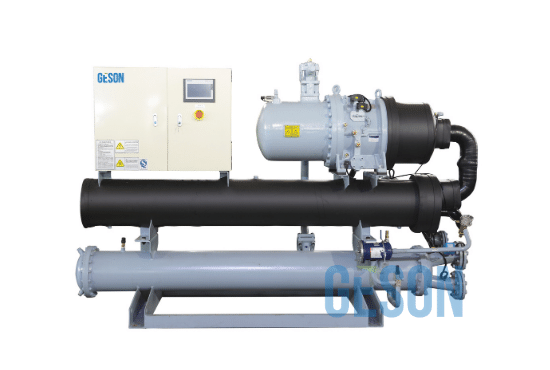

Air Cooled Screw Chiller

- 5RT-4000RT Capacity

- -5~25℃ Outlet Temperature

- PLC Controler

- No Need Cooling Tower

- Easy to Installation

Air Cooled Scroll Chiller

- 3RT-60RT Capacity

- 0~25℃ Outlet Temperature

- Built-in Water Pump and Water Tank Design

- No Need Cooling Tower

Why Choose GesonChiller?

Are you looking for a professional water chiller manufacturer?

Geson Very Best Chillers is one of the leading China Chiller Manufacturers.

Geson chiller systems is leading manufacturer specializing on Industrial water chillers and commercial HVAC water chillers manufacturing for over 15 years.

Geson Chiller systems offer one-stop chiller system solutions with the highest quality and safest products to customers globally.

You can get all types of typical capacities ranging, chilling systems typical cooling capacities from 3 Ton~4500 Ton, and temperature from -145℃~25℃, complete full product series for Geson chilling systems.

Including Water-cooled chillers, Air-cooled chillers, Screw Chillers, Scroll Chillers, Centrifugal chillers, Water(ground) source heat pumps, Air source heat pumps, and etc.

Specializes in:

√ Water-cooled chillers

√ Air-cooled process equipment chillers

√Screw Chillers

√ Scroll Compressors chillers

√ Modular Chillers

√ HVAC Chillers

√ Industrial Water Chillers

√ Air Cooled Screw Chiller √ Air Cooled Scroll Chiller

√ Packaged Chiller Systems

√ Centrifugal chillers

√ Liquid Chillers

√ Evaporation Cooled Chillers

√ Water(ground) source heat pumps

√ Air source heat pumps

√ Swimming Pool Heat Pumps, Swimming Pool Chillers and etc.

GESON Industrial chiller manufacturer offer the high efficiency solution for residential, commercial and industrial applications.

- Plastic-Industrial-Injection- Molding-chiller

- Plastic Processing Blowing-Molding-chiller

- Welding Equipment industrial process chillers

- Chemical Industrial Processes chillers

- Pharmaceutical Formulation Industrial Processes Cooling Applications Chiller

- Food and Dairy Production process cooling equipment

- Beverage Process Cooling Chiller

- MRI-and-Laser-chiller

- Computer-Data-Center-chiller

- Beer-and-Wine-Fermentation-chiller

- Glycol-Beer-Chiller

- Glycol Cooling System

- HVAC Split Units Chiller

- Hospital-Central-chiller

- Hotel-HVAC-chiller

- Campuses-HVAC-chiller

- Swimming-Pool-chiller

- Metal finishing industries Chiller

- Vegetable-and-meat-cold-room-strorage-chiller

Geson has been exported to the Americas, Europe, Middle East, Africa, Southeast Asia, and its, and was praised by customers all over the world.

Looking more products, pls visit our products list. MORE PRODUCTS

If you have more questions about water chillers technical support, free to CONTACT US.

Top Brand Major Components

High Quality Components Ensure Your Top Quality Chiller

All Types of Industrial Water Chiller Products

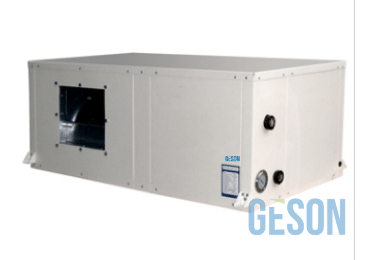

Modular Air Chiller

Geson Water Chiller Manufacturer In China

The Ultimate FAQ Guide

This guide will help you to select the best China high quality chillers manufacturer.

It contains every aspect of the water cooled chillers you have searched for, such as types, size, advantages, and cost.

Interesting fact: we have discussed the comparison of different types of chillers.

Geson chiller units have is widely applied in the Commercial facilities Modular Chillers, Pharmaceutical clean room, Chemical industry, Plastic Injection molding chiller and extruding industry, Artificial Real Ice Rink chiller projects, Environmental simulation laboratory, Computer server room, Telecommunications stations, Food and Beverage processing cooling, Cold storage room, Die casting, Rubber, Printing, Swimming Pool Heat Pump and many other industries.

Before you plan to buy a chiller unit, have a look at this guide.

Contact Us

Refrigerant Charging Methods-GESON Chiller

Refrigerant Charging Methods-GESON Chiller Refrigerant charging is an important and complex step in the installation and maintenance of air conditioning systems and refrigeration systems and chilling equipment systems. It involves adding the correct amount of [...]

Understanding the Key Differences between COP, EER, APF, SEER, IPLV, and NPLV in Air Conditioning Heat Pump Chillers

Difference of COP, EER, APF, SEER, IPLV, NPLV of Air Conditioning Heat Pump Chiller 1. COP (COP=cooling capacity/compressor electric power) The COP value (cooling efficiency) is actually the ratio of the cooling capacity (heating [...]