Why Choose Geson Chiller Cooling System

A chiller cooling system is the best option for large installations such as residential buildings, commercial developments and the like. Take time to learn about how this system works and when this is the best option to be installed.

Geson water chiller has is widely applied in the Commercial facilities, Pharmaceutical clean room, Chemical industry, Plastic Injection and extruding industry, Artificial Real Ice Rink projects, Environmental simulation laboratory, Computer server room, Telecommunications stations, Food and Beverage processing cooling, Cold storage room, Die casting, Rubber, Printing and many other industries.

Contact our engineer, to get the right central chiller system solution for your industry.

All Types of Industrial Water Chiller Products

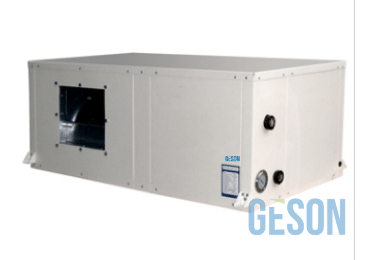

Modular Air Chiller

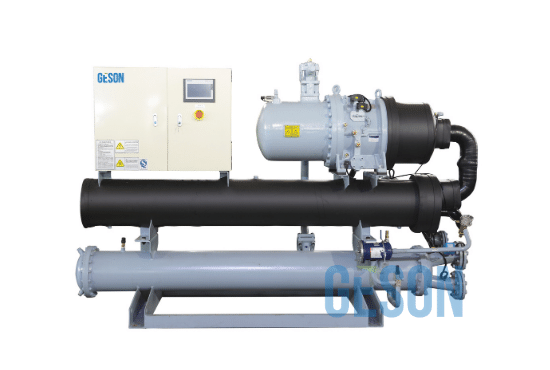

GESON Water Chiller Cooling System

|

|

|

|

|

|

Water Cooled Chillers Datasheet |

|

| Model | GS-530WD |

| Cooling Capacity (kW) | 530 |

| Total Power (kW) | 152 |

| Refrigerant | R410A |

| Compressor Type | Semi-closed 5:6 asymmetric twin-screw compressor |

| Leaving Water Temp (℃) | 7 |

| Entering Water Temp (℃) | 12 |

| Shipping Weight (kg) | 2850 |

| Operating Weight (kg) | 3150 |

| Length (mm) | 4600 |

| Width (mm) | 2000 |

| Height (mm) | 2500 |

Advantages of Geson Chiller

We want to be your expert chiller manufacturer in China

Your Top Quality Chillers Manufacturer In China

Top Brand Components

Ensure Your Top Quality Chiller

Water Chiller Cooling System Supplier in China | Geson Chiller

Below is a collection of questions that you need to address when you are deciding if this system is the best option for your needs. You can use the information provided as a guide and make an informed decision.

Water Cooled Chillers

What Are The Primary System Components?

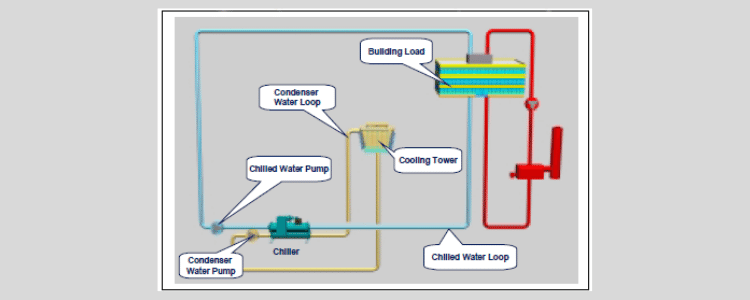

A chiller cooling system consists of several functional parts. The first one is the main chiller unit, which is responsible for cooling the water or fluid. The second one would be the loads, which are satisfied by the coils. They help to transfer the heat from the air to the water.

The use of pumps and pipes are essential in a chiller cooling system. They facilitate in the chilled water distribution and then forwarding that to the loads. The condenser fans are also an important part of the entire system because they help to reject heat to the ambient air.

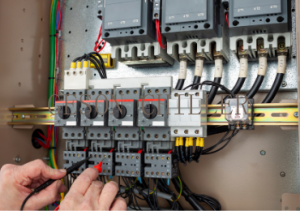

The final component of a chiller cooling system would be the controls. This is where you manage the operation of the entire system’s mechanical components. It also helps to ensure that all of these components are working together as part of the system.

Air Cooled Chiller Diagram

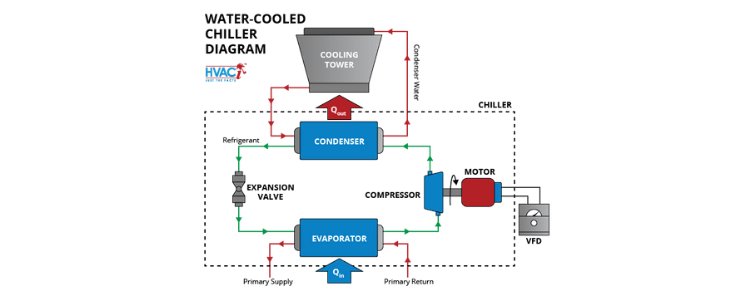

What Is A Chiller Evaporator?

The chiller evaporator is one of the primary components of a chiller cooling system. It is a shell and tube component that is responsible for facilitating the heat exchange process. The tubes can contain either the water or refrigerator depending on the design of the chiller.

What Is The Effect Of Flow Rate And Variation Of Chilled Water?

The water flow rate has a direct impact on the overall function of the evaporator. If there is an excessive flow, it can produce high level of noise, vibration, and water velocity. On the other hand, if there is insufficient flow, it can result to poor chiller performance or low efficiency.

The design of a Water Cooled Chillers is not designed for low flow rates. It is, therefore, important that the water flow meets the minimum and maximum limits set for the system. Before operating the system, take time to learn about these limits based on the manufacturer’s specifications.

How Does Flow Rate Affect The Condenser?

Just like the evaporator, the condenser is also sensitive when it comes to the flow rate. The water flow through the condenser of a chiller cooling system must be kept within the specific range for maximum efficiency.

If the flow rate is too low, it could result to fouling. If the flow rate is too high, it can cause erosion and high vibration. Always aim to operate the flow rate within the specified range to avoid any errors to the system operation.

Chilled Water System

What Is The Ideal Chiller Cooling System For Low-Ambient Temperature?

The installation of air-cooled chillers is the ideal option when the cooling requirements are not satisfied using an airside economizer. Air-cooled condensers are able to operate normally even in weather conditions that are below freezing level. This makes it possible to operate them year-round and also eliminates the need for a cooling tower.

If you are using a chiller cooling system for process applications, air-cooled chillers are your best bet.

Which Chiller Cooling System Is More Energy Efficient?

The water-cooled chillers are your best option when it comes to energy efficiency. An air cooled chiller relies on the ambient dry-bulb temperature whereas the water cooled chiller relies on the ambient wet-bulb temperature.

The latter is significantly lower so it is less susceptible to variations in the existing weather conditions. For this reason, it can operate all year round and has lesser fluctuations, making it easier to operate with higher efficiency rating.

Figure 2 – Water Chiller Cooling System

How Do You Control Heat Transferred From The Loads?

There are a number of ways to transfer heat from the loads and they are as follows:

- Three-way valve – The three-way valve is responsible for regulating the water that enters the coil in response to loads. It needs a consistent flow of water to enter the system regardless of the load. The only downside here is the reduced water temperature once the water leaves the three-way valve.

- Two-way valve – This is a modulating valve that performs the same function as the three-way valve. While there is no difference in how the coil reacts to the valve’s function, its effect is felt on the chilled water system. The water that comes out from the valve is higher (when compared to the three-way valve).

- Variable speed pump – The pump speed is varied in order to control the flow towards each coil. This means that there is a lack of control valves at the coil. This will significantly cause the pump and maintenance cost to rise.

- Face-and-bypass dampers – The use of a damper helps to control the amount of conditioned air supply that passes through the coil surface. This helps to improve the dehumidification of part loads while also eliminating the need for control valves.

- Chiller Cooling System Diagram

How Do You Maintain Chiller Cooling System?

There are specific steps that must be taken to ensure that a Water Cooled Chillers is running efficiently. Proper maintenance is on top of that.

The first step for proper chiller cooling system maintenance is to ensure that the main parts are in good condition. Regularly check the exhaust and inhale pressure. By doing maintenance, you will be able to identify issues before they impact the entire system.

Water Chiller System

Check the wires to see if any of them had gotten loose. Make sure the electrical components are in good condition or if they need any replacement. It is also important to do some descaling, especially for water-cooled chillers.

You need to develop a specific maintenance approach suited for the season. During winter, make sure the inside and outside surfaces are properly cleaned. Avoid freezing by draining all the water within the shell and tube heat exchanger.

Check all controls to ensure that they are operational and running efficiently. It pays to read the manufacturer’s instructions on how to care for and maintain a chiller cooling system.

Water Cooled Chiller System

How Does Chiller Cooling System Differ From Air Conditioners?

A chiller cooling system should not be confused with an air conditioner. An air conditioner is designed to regulate the temperature within a room. Some models can also dehumidify the specific area being cooled. Most systems use water as the principal refrigerant.

With a chiller cooling system, it uses the vapor-compression or vapor-absorption refrigeration cycle to generate cooling. It is built for cooling larger spaces such as an entire building or manufacturing plant. They are either air-cooled or water-cooled chillers.

There are four types of methods to power a chiller cooling system: screw-driven, reciprocating, centrifugal, and absorption. The chiller is responsible for managing the flow of heat and cooled air within a given space.

Needless to say, the difference between the chiller and the air conditioner are very subtle, in terms of the methods of cooling. The applied usage is where the difference truly lies.

Chiller System Diagram

How Do You Control The Chilled Water System?

The controls of a chiller cooling system are designed for more functionality other than switching the system on or off. It enables you to optimize the performance of the entire system to avoid highest performance and efficiency.

First off, there is safety point control. It is responsible for maintaining the proper range of electrical points and temperature to ensure that the entire is running properly and to avoid failure of the system.

The data points are another area of control available in a Water Cooled Chiller System. This is the control that you adjust whenever there are operational problems. The data points enable you to take corrective action to restore the unit’s function.

Finally, there are general points control that facilitates the proper chiller performance.

Chillers Cooling System

How To Select The Right System Size?

Choosing the right system size is important to determine the right control settings needed and to know its appropriate application.

A small chiller system typically comes with 1 to 2 chillers. This is the ideal choice if you want to keep the entire system simple and to control energy consumption. This size of system is recommended for those operations with smaller budgets since they require less maintenance.

The mid-sized chiller system is ideal when the small sized ones are inefficient to meet the cooling load requirements. Before you choose this size of chiller cooling system, it is important to get in touch with highly skilled operators. They will be able to understand the proper methods of care and maintenance for a more complex system.

A large sized Chilled Water System is when you need 6 or more chillers. It is also the common choice for buildings that require district cooling. This type of chiller cooling system is commonly found in downtown districts, multiple buildings, university campuses, commercial developments, and mixed-use buildings.

Building a large chiller system requires a lot of planning and foresight. In fact, it might involve a multi-year master plan in order to satisfy future loads and building expansion. There are numerous factors to consider when installing a chiller cooling system this size such as pipe size, water source, power availability, and controls.

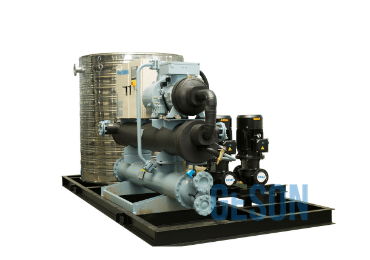

Figure 3 – Industrial Chiller Cooling System

When To Install Multiple Chillers Cooling System?

The installation of multiple chillers is recommended in the eventuality that a single chiller unit does not meet varying load requirements. When this happens, it would not be cost-effective to run a single Water Chiller System.

The use of a chillers cooling system is the best option for a large-scale application of cooling for multi-use buildings, whether for commercial, manufacturing or residential use. The parallel staging of multiple chillers is also a good option to achieve peak load. Both of these options are ideal for larger installations.

The option to install multiple chillers is chosen for handling equipment failure and routine maintenance. A good example is to install one chiller at one-third of the load and one more with two-thirds of the load. This is a measure done to ensure that the building’s part load requirements are satisfied.

Chiller Heating And Cooling System

It is important to speak to a manufacturer about your options so that they can be sized optimally. This is to ensure that you can meet different cooling conditions as part of the chillers cooling system.

Aside from satisfying the cooling requirements of the building, it is also important to consider the potential energy savings. You must take into account the number of hours operation for the system.