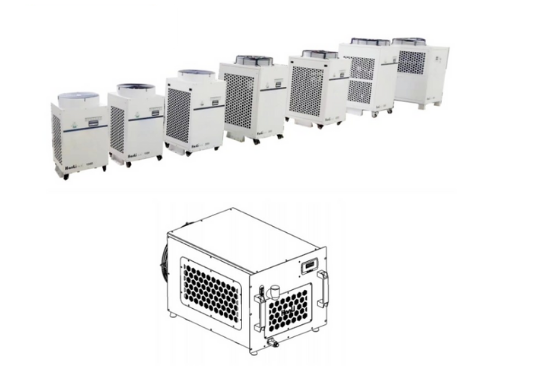

GESON Mini Chiller

Specially Developed for Fiber Laser Equipment

Stable And Reliable Performance

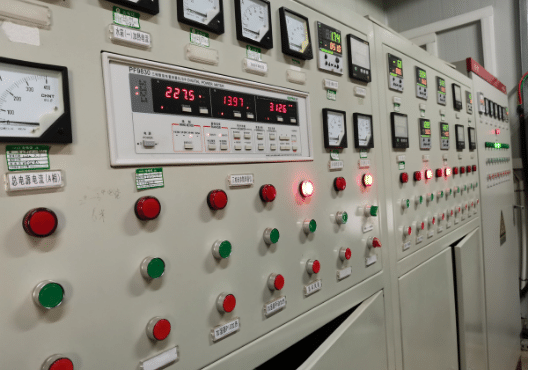

Laboratory Testing in Factory

Two-year Free Maintenance

Accurately Compatible With All Brands of Lasers

Our History:

Geson Chiller Has Over 10 Years of Experience in Industrial Water Chiller Manufacturing.

Geson Chiller Has a Professional R&D Engineering Team and a National-level Test Laboratory.

Owned Top-level Advanced Manufacturing Equipment and CNC Machining Center, Computer Numerical Control Punch and Bending Machine, Automatic Welding Machine.

Geson Chiller has been the leading industrial water chiller manufacturers in China.

Our Products:

Geson chiller is focused on Industrial/Commercial Refrigeration Equipment HVACR systems, Supply Industrial Process Cooling Solutions, and Commercial HVAC Solutions.

Capacity from 2 Tons~4000 Tons, and Temperature From -160℃~30℃, Complete Full Product Series

Our Service:

Answer Within 30 Minutes to Respond,

2 Hours to Give A Solution,

48 Hours to Get A Return Call.

Ensure You Get the Best Water Chiller Working Performance.

Main Products

| Mini Chiller System

Model |

GS1000MN Mini Chiller |

| Voltage & Frequency | 1p 220V @ 50hz |

| Current | 10.5A |

| Machine power | 2.3kw |

| Application environment | working temperature≯45℃&≯95%RH |

| Tempe. control accuracy | ±1℃ |

| Cooling capacity | 3150w |

| Electric heating power | 650w(Normal Ambient Temp) |

| Refrigerant | R410a |

| Rated flow of water pump | 2m³/h |

| Max.pump lift | 27M |

| Pump power | 0.37kw |

| Tank volume | 13L |

| Laser nozzle interface | φ12mm Quick connector |

| Cutting head nozzle interface | φ10mm Quick connector |

| Machine weight | 55KG |

| Machine size | 580*490*860mm(L*W*H) |

| Packing dimensions | 630*560*950mm(L*W*H) |

|

Functional characteristics |

Efficiency and environmental protection;

Double temperature controls; Flow & over temperature alarm; Thermal protection of compressor; Leakage protection device. |

| Recommended matching | 1kw Continuous fiber laser |

Small Chiller 5~35℃

Precision Chiller 5~35℃

Laser Chiller 5~35℃

Split Chiller 5~35℃

Enhanced Chiller 5~80℃

Application:

* Analytical instruments: electron microscope, spectrometer, mass spectrometer, viscometer, polarimeter, diffractometer.

* Vacuum acquisition and medical treatment: cooling blanket, X-ray machine, nuclear magnetic resonance, accelerator.

* Industrial equipment and others: laser equipment, vacuum coating equipment, biopharmaceuticals, molds, machine tools, vacuum furnaces, welding machines.

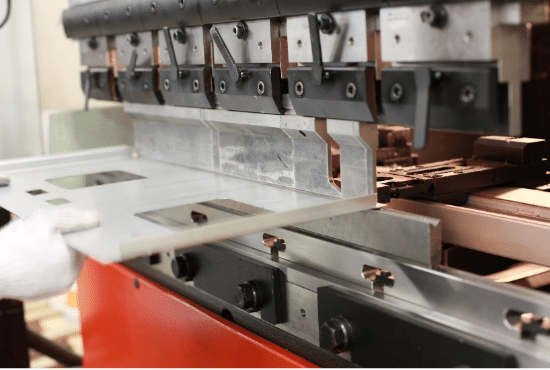

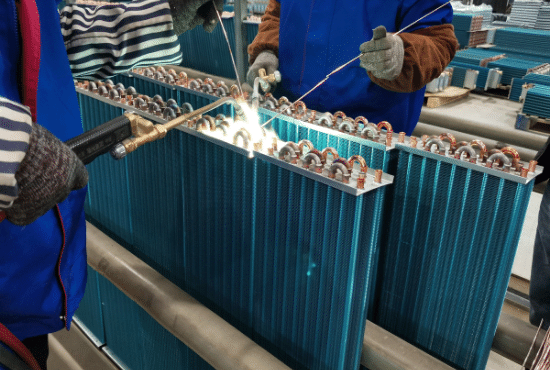

Our Manufacturing

Excellence Quality is Our Principle

Sheet Metal Bending Machie

Automatic Copper Pipe Machine

Water Chiller Heat Exchanging Welding

Finned Heat Exchanger Welding

Water Chiller Testing Labritary

Top Best Mini Chiller For Sale – Buyer’s Guide

What is a Mini Chiller?

A mini chiller is a type of industrial chiller that is designed to cool water.

It’s a water cooling cooler.

A mini chiller is typically used in industrial settings where cooling water is needed.

It’s often used in the food industry, power plants, and manufacturing facilities.

A mini chiller is a type of chiller that is used in the industrial sector.

These chillers are usually used in food processing and dairy industries, and they are also used in laboratories.

A mini chiller system uses a refrigerant gas to produce cold water from a compressor.

The refrigerant gas is circulated through coils that are submerged in the water, and this cools the water by transferring heat from it.

This cold water is then pumped to an evaporator where it passes through coils that have been submerged in a liquid refrigerant.

This causes the refrigerant to vaporize and condense, which releases heat into the air, which makes it colder than when it entered the evaporator coil.

The cooled liquid refrigerant then flows back into the compressor to repeat this process over again.

Air cooled mini chillers are the most common type of mini chiller.

They use air to cool the refrigerant and are usually used for small applications like in homes, offices, hospitals, etc.

Water cooled mini chillers use water to cool the refrigerant and are used in industrial settings.

They have a higher cooling capacity than air cooled mini chillers but they require more space and a larger installation.

High pressure (HP) mini chillers are also known as vapor-compression or absorption machines.

These machines use high pressure to compress liquid refrigerant into a gas which is then cooled before being compressed back into a liquid state and pumped to the evaporator where it absorbs heat from the process stream and turns it into cold temperature energy.

What is a Mini-Chiller and What Can it do for You?

A mini chiller is a small recirculating chiller that can be used for small cooling applications.

It is typically used in laboratories, data centres, and other industrial settings.

The main function of a mini chiller is to provide cold water for the cooling system for air conditioning.

It also cools the condenser coil which cools the refrigerant gas before it enters the evaporator coil and it provides chilled water to maintain the temperature of a building’s central air conditioning system.

A mini-chiller is an efficient way to cool small spaces when there isn’t enough room or funds for installing a large unit.

How to Choose the Best Mini Chiller for Your Needs

The best mini chiller is the one that is right for your needs. There are many options out there, and it can be difficult to choose one. The key to finding the best mini chiller is to consider what you need it for and how often you need it.

The Benefits of Mini Chillers for Industrial Use

Chillers are used to cool down liquids or gases. The industrial chillers are used in various industries like petroleum, chemical, food and beverage, pharmaceutical and others.

Industrial chillers can be classified into two types: air-cooled and water-cooled chillers. Air-cooled chillers use cold air to cool down the fluids while water-cooled chillers use a closed loop system.

The benefits of using industrial chillers are:

1) They help in increasing the productivity of the industry by reducing the downtime due to overheating of equipment,

2) They reduce energy consumption by cooling the fluids before they enter the equipment.

Introduction to Mini Chiller and Mini Recirculating Chiller

Mini chiller is a small-sized chiller that is used in smaller applications and for people who need to chill a small amount of water.

Mini recirculating chiller is a type of chiller that uses refrigerant to cool the water and then pumps it back into the system in order to keep it cool.

The mini chiller is more efficient than the mini recirculating chiller because it does not need any electricity to run.

The mini recirculating chiller, on the other hand, needs electricity in order to work.

What is the smallest chiller?

The smallest chiller is a mini-chiller.

It is a small and portable device that can be used to cool down drinks.

A mini-chiller is not just the smallest, but it is also the most convenient type of chiller.

It can be easily carried around and it’s perfect for picnics and parties.

What are the three basic types of chillers?

There are three basic types of chillers: air-cooled, water-cooled, and refrigerant-cooled.

Air-cooled chillers are the most common type of chiller on site.

They use ambient air to cool the refrigerant and condenser water.

Air-cooled chillers can be used in areas with high ambient temperatures and low humidity levels because they do not need a cooling tower or cooling water supply.

Water cooled chillers use a cooling tower and chilled water as their primary means of heat rejection.

These systems are popular for areas where there is a shortage of suitable natural sources for air cooling, such as desert regions or coastal locations with high humidity levels.

Refrigerant cooled chiller uses an ammonia compressor to compress the refrigerant gas.

What are the small chiller aquarium?

A small chiller aquarium is a type of fish tank that can function as an outdoor pond or indoor aquarium.

It is often used by people who don’t have a lot of space for a large tank and want to keep their fish contained in one place.

The small chiller aquarium can be made from any material,

but the most common are acrylic and glass tanks.

The size of the tank is usually not larger than 10 gallons, which is perfect for a small space or an office desk.

What are the mini glycol chiller?

Mini glycol chiller are a type of refrigeration that can be used for cooling and freezing food or other items.

Mini glycol chiller can be used to cool and freeze food items that require a specific temperature to maintain the quality.

They are also often used in laboratories for various experiments.

The most common use of these mini glycol chiller is in the lab setting when scientists need to keep their samples at a certain temperature or below.

What is Mini Chiller AC?

A mini chiller is also known as a portable air conditioner and it works by pumping cold water through the system and then releasing it into the room.

The cold water evaporates and cools the air, making it more comfortable for people to be inside.

The main difference between this type of air conditioner and other types is that it does not have any ducts or pipes.

This means that you can use this type of air conditioner in any space without having to worry about installation issues.

What are Mini Aquarium Chillers and How Do They Work?

The Mini Aquarium Chiller is a cooling system for your fish tank that helps maintain the desired temperature in your aquarium.

It is designed to be small and efficient, making it perfect for smaller tanks.

The Mini Aquarium Chiller employs a water-to-air heat exchanger to cool down the water in the tank.

This can be done by circulating the water through a tube that has cold water running through it, or by using an electric pump to circulate the warm water from the bottom of the tank up and out of it.